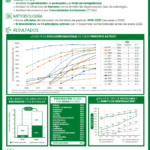

The development of a biosimilar medicine requires the execution of exhaustive studies in which the biosimilar candidate and the original reference product are compared. This comparison is carried out both during the initial stages of development, in which the molecular and functional characteristics are evaluated, as well as in the non-clinical and clinical stages. This process is known as a 'comparability exercise'. The objective is to demonstrate that the biosimilar is equivalent to the reference product in terms of quality, efficacy and safety.

Throughout the whole 'comparability exercise' the same reference medicine is used, the first step being the quality comparability: that is, in essence, the comparison of the physicochemical characteristics and biological activity, among other studies. Given the relevance of this stage of development to determine comparability, the studies required in the quality module for biosimilars are usually significantly more extensive than those required for an original product.

This should demonstrate that the differences that may exist in quality are minor and in all probability insignificant from a clinical point of view. If the differences at this stage of the exercise are potentially worrisome, the necessary modifications must be made in production to increase molecular similarity. Must be complied with at all times criteria required by the European Medicines Agency (EMA).

The second stage is the non-clinical comparability. These are non-clinical studies whose objective is to confirm that possible slight differences do not modify their toxicity profile in vivo (in experimental animals). At this stage, other aspects related to the pharmacology of both compounds can be compared (for example, their activity, their local tolerance, etc.).

The third and final stage in the development of a biosimilar is the demonstration of clinical comparability. Comparative clinical trials make it possible to confirm what the most sensitive tests indicate; that both products essentially share the same active ingredient and that their efficacy and safety are equivalent. It is not a question of once again demonstrating the efficacy and safety in people, since they have been demonstrated in the original reference product, but of demonstrating that the clinical behavior is equivalent. The accumulated knowledge and experience with the original product, together with the exhaustive demonstration of structural and functional comparability allow adapting the non-clinical and clinical stages on a case-by-case basis and therefore shortening some of the studies. Therefore, it would not make sense to require the same clinical tests from a biosimilar that would be necessary for a new active ingredient.

The design of the clinical development program therefore takes into account the nature and characteristics and its intended use, and also how comparable the profile of the biosimilar medicine is to that of the reference product. The customized or abbreviated clinical studies They help ensure that unnecessary human testing is not carried out.

If the medication is authorized, the marketing owner (laboratory) must implement a follow-up of treated patients (pharmacovigilance) that allows certifying that this equivalence is also substantiated in post-marketing clinical practice.